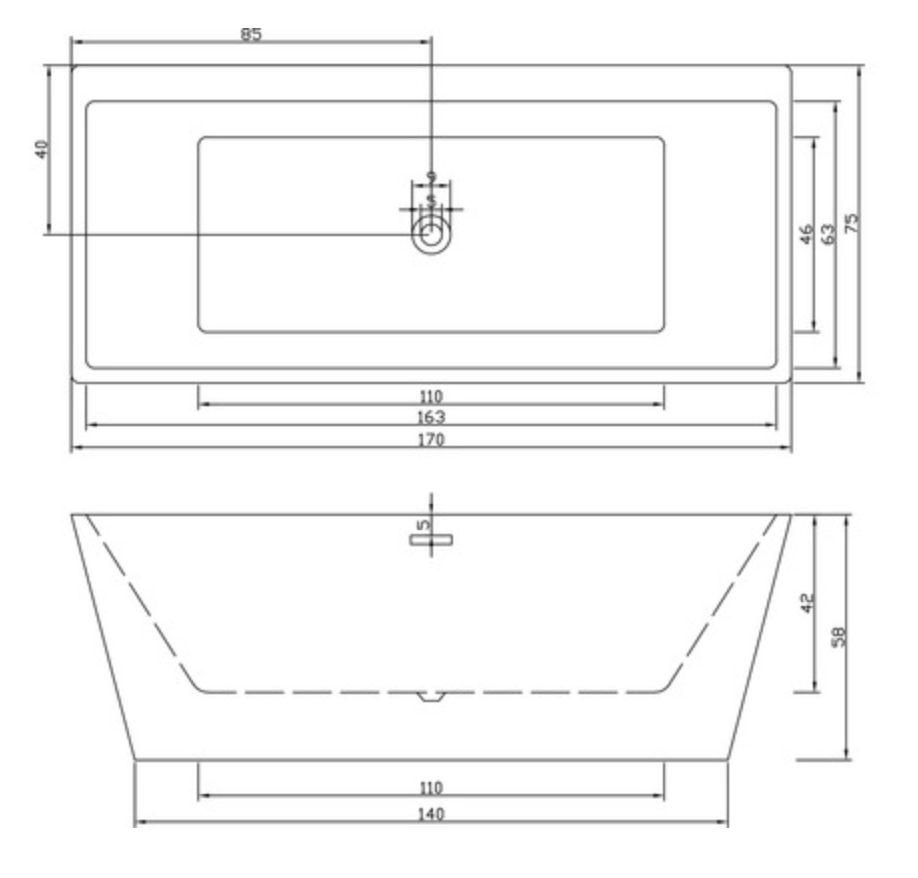

Freestanding bathtub MIAMI 170x82x58.5 cm

Regular price

€ 555,33

Sale price

€ 555,33

Regular price

€ 1.093,81

Freestanding bathtub OXFORD 178x88x83 cm

Regular price

€ 713,99

Sale price

€ 713,99

Regular price

€ 1.093,81

Freestanding bathtub PARIS 170x80x58.5 cm

Regular price

€ 756,64

Sale price

€ 756,64

Regular price

€ 1.078,94

Freestanding bathtub LIVERPOOL 170x80x60 cm

Regular price

€ 561,28

Sale price

€ 561,28

Regular price

€ 997,61

Freestanding bathtub EMPIRE 170x75x75 cm

Regular price

€ 498,81

Sale price

€ 498,81

Regular price

€ 1.230,66

Freestanding bathtub STYLE 170x75x59 cm

Regular price

€ 551,36

Sale price

€ 551,36

Regular price

€ 956,96

Freestanding bathtub ORLANDO 180x85x61.5 cm

Regular price

€ 971,84

Sale price

€ 971,84

Regular price

€ 1.093,81

Bathtub apron to LONDON / LIVERPOOL

Regular price

€ 123,95

Sale price

€ 123,95

Regular price

€ 148,75

Side skirt for LA PALMA 149

Regular price

€ 132,88

Sale price

€ 132,88

Regular price

€ 230,06

Bathtub LINEA MAXI 170x75x41 cm

Regular price

€ 132,88

Sale price

€ 132,88

Regular price

€ 162,64

Bathtub MARBELLA 170/180

Regular price

From € 149,25

Sale price

From € 149,25

Regular price

€ 254,86

Bathtub ORIENT 170 / 180 / 190

Regular price

From € 138,34

Sale price

From € 138,34

Regular price

€ 295,51

Corner bath LONDON 165x95x45.5 cm

Regular price

€ 210,23

Sale price

€ 210,23

Regular price

€ 290,56

LIVERPOOL corner bath 165x95x45.5 cm

Regular price

€ 210,23

Sale price

€ 210,23

Regular price

€ 290,56

Corner bath FIRENZE 120 / 130

Regular price

From € 245,93

Sale price

From € 245,93

Regular price

€ 343,11

Corner bath MENORCA 140x140x45 cm

Regular price

€ 249,89

Sale price

€ 249,89

Regular price

€ 351,05

Corner bathtub RIVERA 140/150

Regular price

From € 253,97

Sale price

From € 253,97

Regular price

€ 351,05